Go Big or Go Home! A common misconception in the energy management industry is to see any difference in energy consumption you have to make massive, drastic changes to the way you currently do things. While that can sometimes be the case, it isn’t always the case. Walk-in coolers and freezers can be a difficult area to make changes. Having strict regulations on temperatures foods are supposed to be ensuring your equipment is running smoothly makes this a much more crucial checklist item.

We were asked to help a franchisee who wanted to decrease overall energy consumption in two of their locations. After chameleon was installed, we started to get some insight into the different locations, helping us develop a strategy that would work for hand-in-hand with the business and save money simultaneously. After monitoring their coolers and making an adjustment of only a two degree increase, one location saw an energy reduction of 24%, while the other locations saw a 19% reduction in energy consumption.

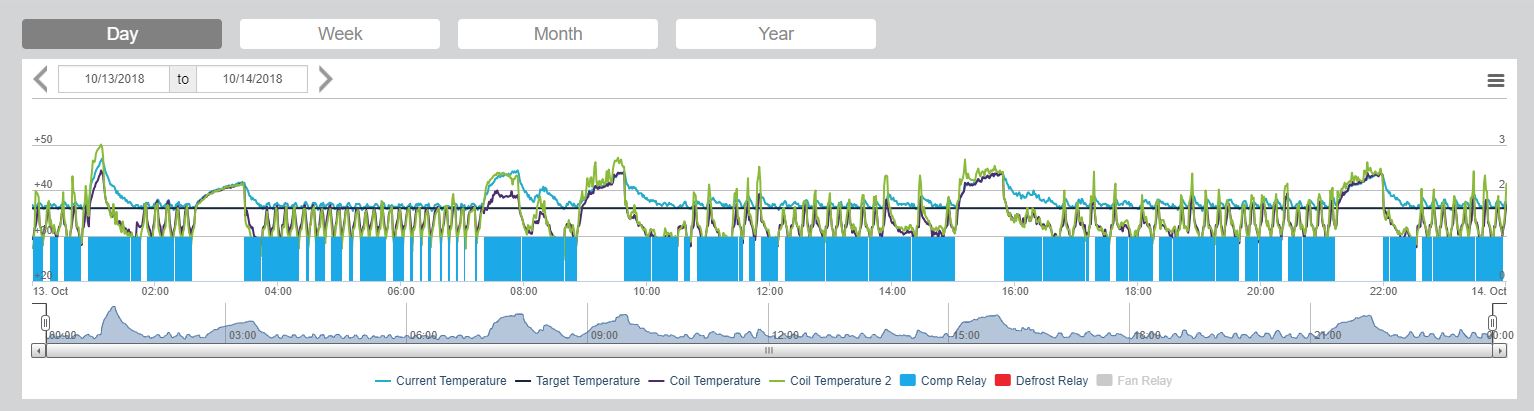

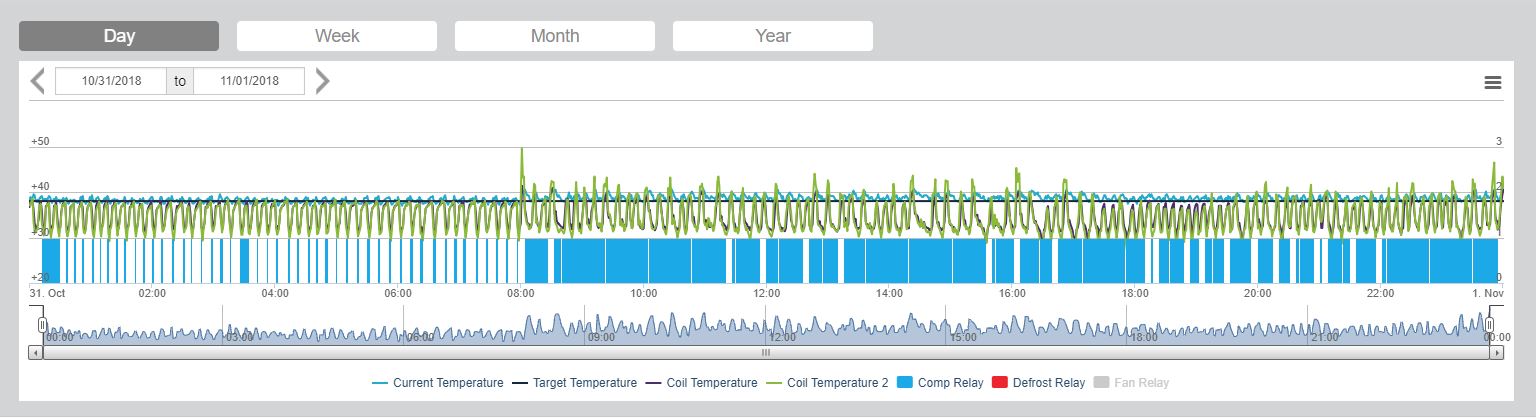

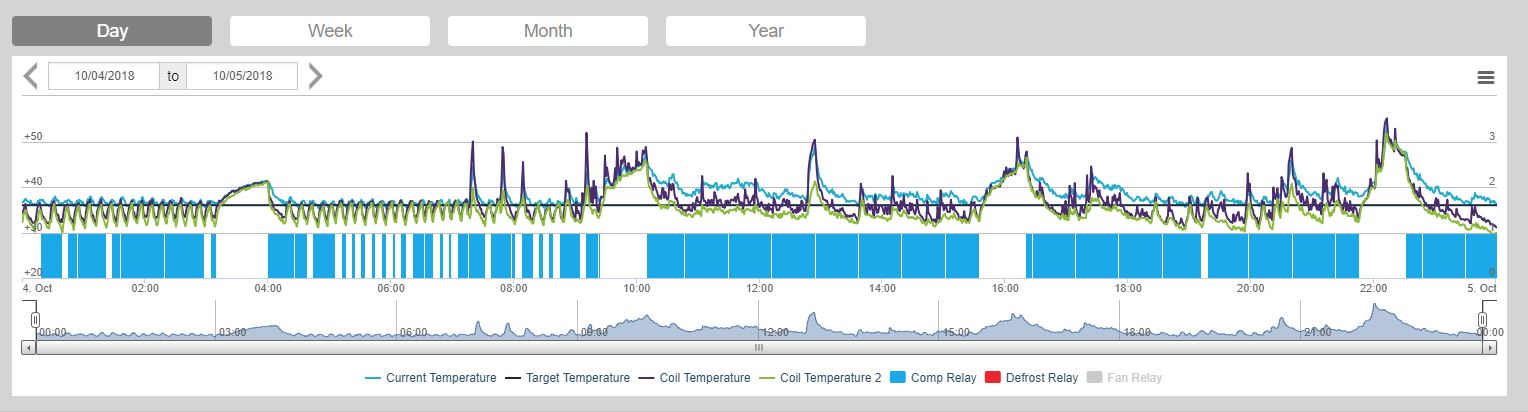

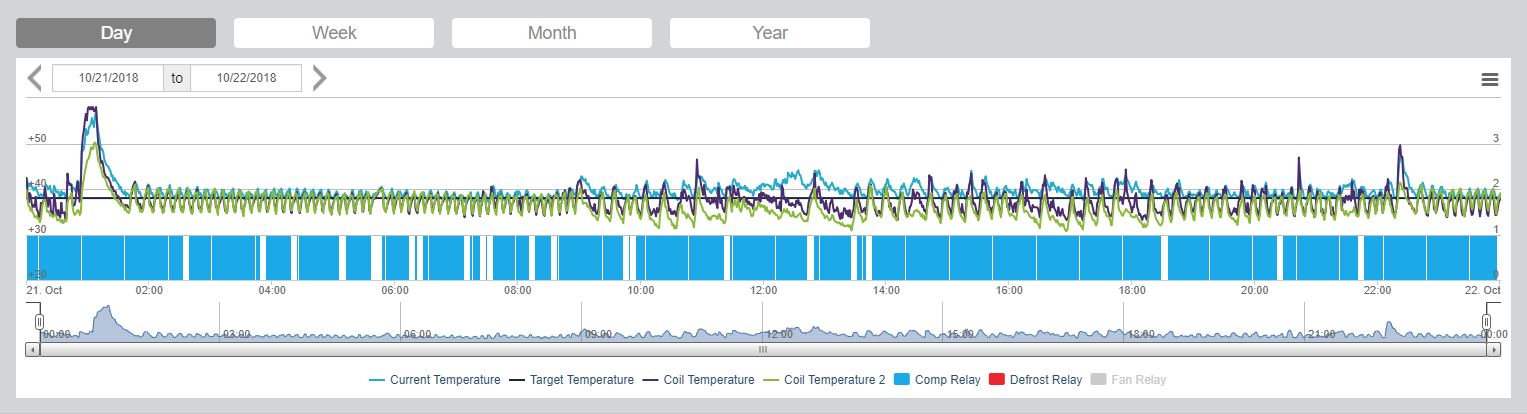

Below you can see the graphs of the before and after of each location. The three different colored lines and blue boxes just below the lines. The blue boxes represent when the compressor in a walk-in unit turns on, the green and purple line represent the two different coil temperatures and the grey line represents the unit target temperature. You can see the temperature of the coils, which represent the temperature inside the unit, aren’t very consistent when the unit goes into a defrost. The temperatures go up which can affect the quality of the food, and if they go up high enough, they could end up being a health code violation.

Before

After

The client success team increased the temperature by just 2 degrees for the units at both locations in hopes they would see a change in the behavior of each of the compressors and stabilize temperature swings. By adjusting the blue slider above you can see the change helped the temperatures level out at both locations in the before on the left and the after on the right. Just by adjusting the temperature of the cooler the unit didn’t have to work as hard defrosting to try to keep the temperatures consistent. The temperatures for the coolers are more consistent and never creep up into the danger zone because of the frequent defrosts.

This small change did more than keep foods out of the danger zone. The quality of the food was increased because it wasn’t being subjected to multiple thaws and freezing again. The equipment life was elongated because the compressor didn’t have to work as hard to try to maintain a temperature it wasn’t reaching. Ultimately, energy consumption was lowered by decreasing the number of defrosts the unit went through daily.

This small change did more than keep foods out of the danger zone. The quality of the food was increased because it wasn’t being subjected to multiple thaws and freezing again. The equipment life was elongated because the compressor didn’t have to work as hard to try to maintain a temperature it wasn’t reaching. Ultimately, energy consumption was lowered by decreasing the number of defrosts the unit went through daily.