Diagnostics benefits include:

- Reduction in unexpected emergency repair needs

- Distinguishing between operating inefficiency and equipment maintenance/repair needs

- Strategically routing repair trucks or service technicians based on need and urgency, reducing labor time and costs

- Reducing routine maintenance costs through data evaluation and performing maintenance when it is actually needed, instead of on a routine schedule

- Early identification of repair needs before it damages other motors and parts

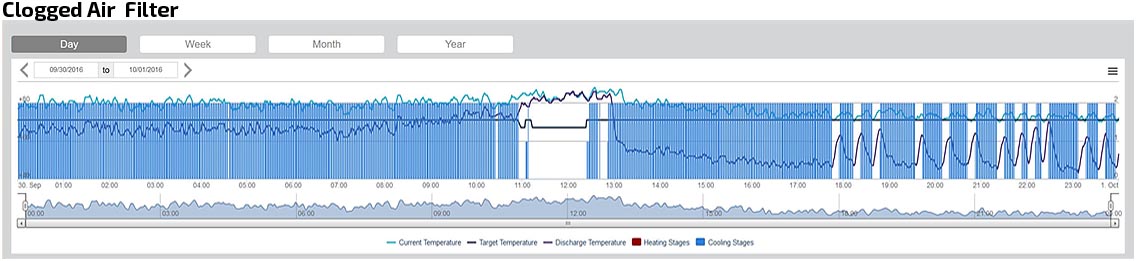

Dirty vs Clean Air Filter

Move the green slider between the 2 images, notice the difference between the two images:

- The Turquoise line is the Current Temperature

- The straight Black line is the Target Temperature

- The Purple line is the Discharge Temperature (this should be 15-20° below the target temperature)

- The Blue lines are when the unit is in the Cooling Stage

Clogged Filter: The HVAC unit’s performance before the filters were changed out. The room temperature (turquoise line) in the upper graphic never hits the target temperature (black line) although the system is running two stages (vertical blue lines) throughout the day and good “splits” are experienced.

Clean Filter – Same HVAC unit 3 days later with new filters. Room temp (turquoise) is now able to reach target temperature (black) consistently while also running approximately 50% less. (Vertical blue lines has been reduced from 21 hours to 11 hours over the same length of time) Kitchen staff also shared that their tickets were blowing around due to air flow much more than they had seen in the past.

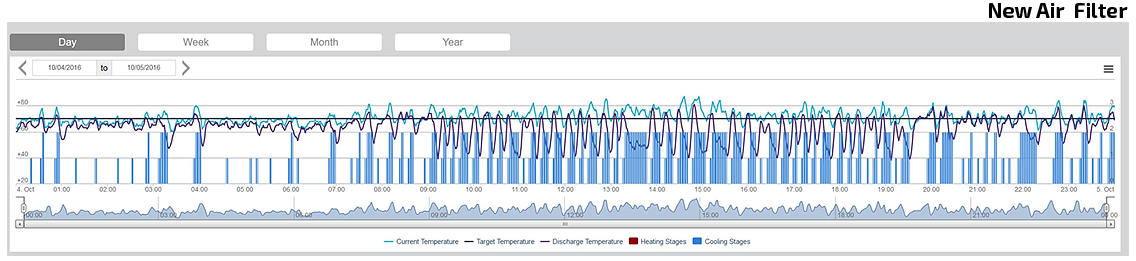

Faulty Compressor

Notice the difference between the two sides of the image; before and after repair:

- The Turquoise line is the Current Temperature

- The straight Black line is the Target Temperature

- The Purple line is the Coil Temperature

When the cooler is running properly, the coil temperature reaches the target temperature consistently.

Ice Buildup

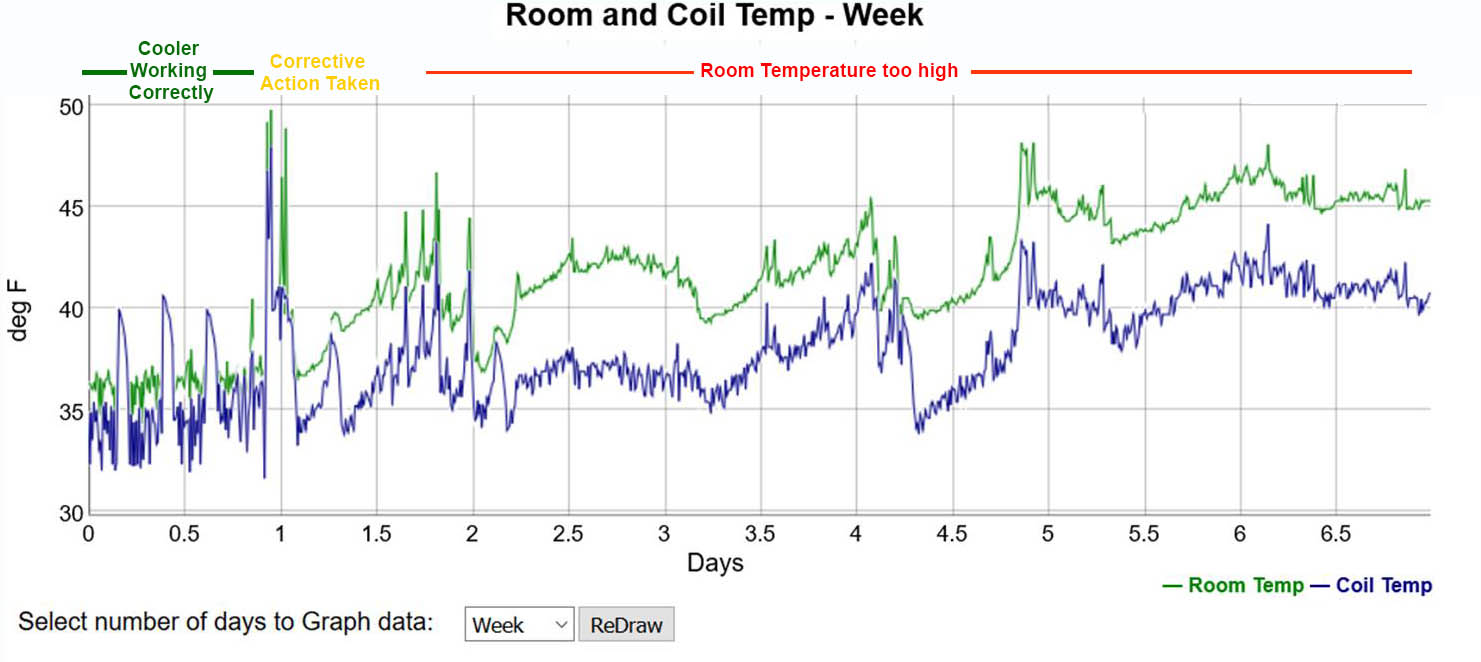

Look at the image from right to left.

- The Blue line is the Coil Temperature

- The Green line is the Room Temperature

The room temperature of the cooler was ranging from 40-50˚ consistently with continual ice build-up because the door was being left open. After this was corrected; you see 3 spikes to 40 degrees in the blue coil temperature; this means the unit was in the proper defrost mode. You will also see the coil temperature is well below the room temperature and consistently staying between 33-35 degrees.

Why are our services valuable to your business?

We actively work to reduce energy costs, provide real-time equipment diagnostics and temperature monitoring and alerts. We will save you time and money on maintenance. Our award-winning chameleon platform was designed specifically for restaurants and convenience stores and continues to evolve to provide greater operational benefits than any other energy efficiency product available. Request a presentation today.