Ice Buildup on the Coil Explained and Solved Using IoT

Recently, our tech support received a phone call from a customer. Their walk-in cooler seemed to be running ok, but he was concerned about all the ice on the coils. Our tech support pulled up the data from the refrigeration module.

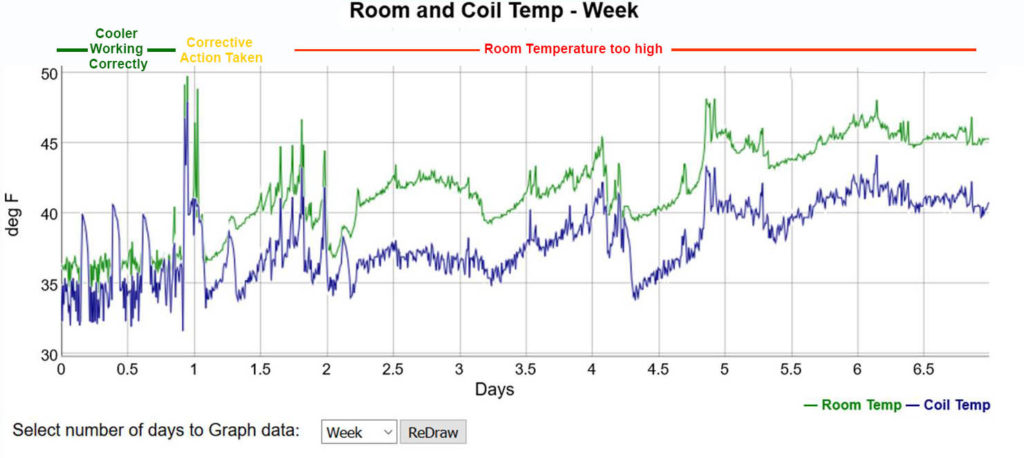

A quick analysis of the graph instantly showed the problem. See the actual graph below. It reads right to left, and is for a period of 7 days. The blue line is the coil temperature and the green line is the room temperature. The room temperature of the cooler was ranging from 40-50˚ consistently. This means the door was being left open from employees. The employees were instantly trained to correct their behavior and stop leaving the door open.

Results:

If you look at the left side of the graph from 0-1, you see 3 spikes to 40 degrees in the blue coil temperature; this means the unit was in the proper defrost mode. You will also see the coil temperature is well below the room temperature and consistently staying between 33-35 degrees.

This corrective action saves money because the cooler isn’t working as hard to lower the temperature of surrounding spaces or freezing up resulting in visits by technicians. We would also expect a longer life of the cooler and compressor because it is not running all the time. Additionally, we might expect the food quality to improve and reduce the chance for a loss of produce, as the cooler is now maintaining a consistent temperature.

Why Does Ice Form?

Ice can form on the evaporative coil due to added humidity from surrounding environments. The developing moisture on the coil causes the ice buildup. In this case the door was being left open, so the ice was forming as the evaporative coil was trying to maintain temperature.