It’s probably the most common complaint in any restaurant, “it’s too cold in here!” Of course, almost everyone’s comfort level is different; however, we can agree that there are some acceptable standards for restaurants. We can also agree that the room temperature should be even across the room(s) for everyone’s dining pleasure. But achieving those standards can be very challenging.

Many people don’t understand air conditioners rely on sensors placed in the room and to balance the comfort across the space, the sensors need to be located correctly. For example, if there is a room with a lot of windows and sunlight; a sensor should be located near that area and at the opposite end of the room where these is no sunlight/heat from the windows. Similarly, you wouldn’t want to place a sensor near the door to the outside because heat/cold air rushing in from the outside will affect the space temperature. Therefore, placing the sensors strategically around the room enables an average to be taken and used as the input, so the HVAC unit can determine how long to blow cool air and effectively cool the space evenly.

Typically, this isn’t something business owners worry about – I mean let’s face it we have enough on our minds as it is. When the HVAC units are placed, the contractors place the sensors based on traffic flow and building factors to optimize your efficiency and comfort. But overtime, these sensors could stop working, be moved by other contractors, or the space itself could have been modified or changed. That is why having remote diagnostics can help you determine when your HVAC unit is running efficiently due to sensors.

Case Study: Remote Diagnostics Uncovered Sensors Placed Incorrectly

Problem: Managers told the Small Box Energy Client Success Manager (CSM) they felt the space was warmer than the thermostats indicated, and often had trouble keeping the space at a comfortable temperature for customers.

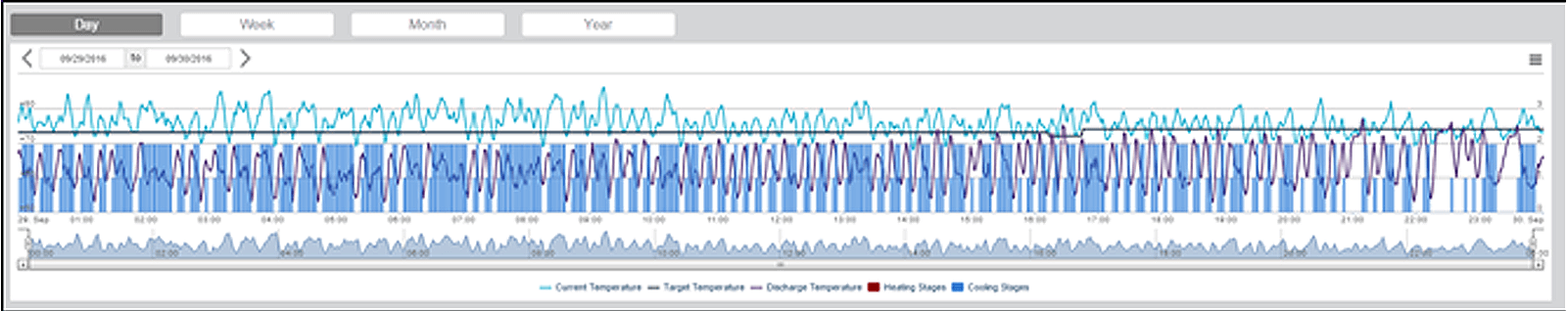

Upon inspection of the equipment through remote diagnostics, the CSM could see the target room temperature was barely being reached and the compressors were running constantly in 2 stages of cooling.

Diagnosis: When the technician visited the space; they found the sensors were located incorrectly causing the room temperature being reported to be drastically different than if the sensors were placed properly.

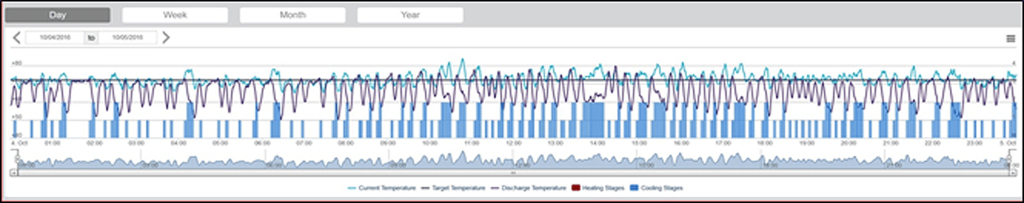

Solution: The SBE technicians relocated the sensors, and the CSM noticed a significant difference in run-time for the compressor and the unit is now consistently reaching the target temperature.

Additionally, the managers have reported back that the room temperature feels comfortable.

The Turquoise line is the Current Temperature

- The straight Black line is the Target Temperature

- The Purple line is the Discharge Temperature (this should be 15-20° below the target temperature)

- The Blue lines are when the unit is in the Cooling Stage

For more information on how Small Box Energy can help you save energy and money through remote equipment diagnostics, contact us today.